About Tiangcheng International Technology: Your Certified Global Partner in Silicone Manufacturing

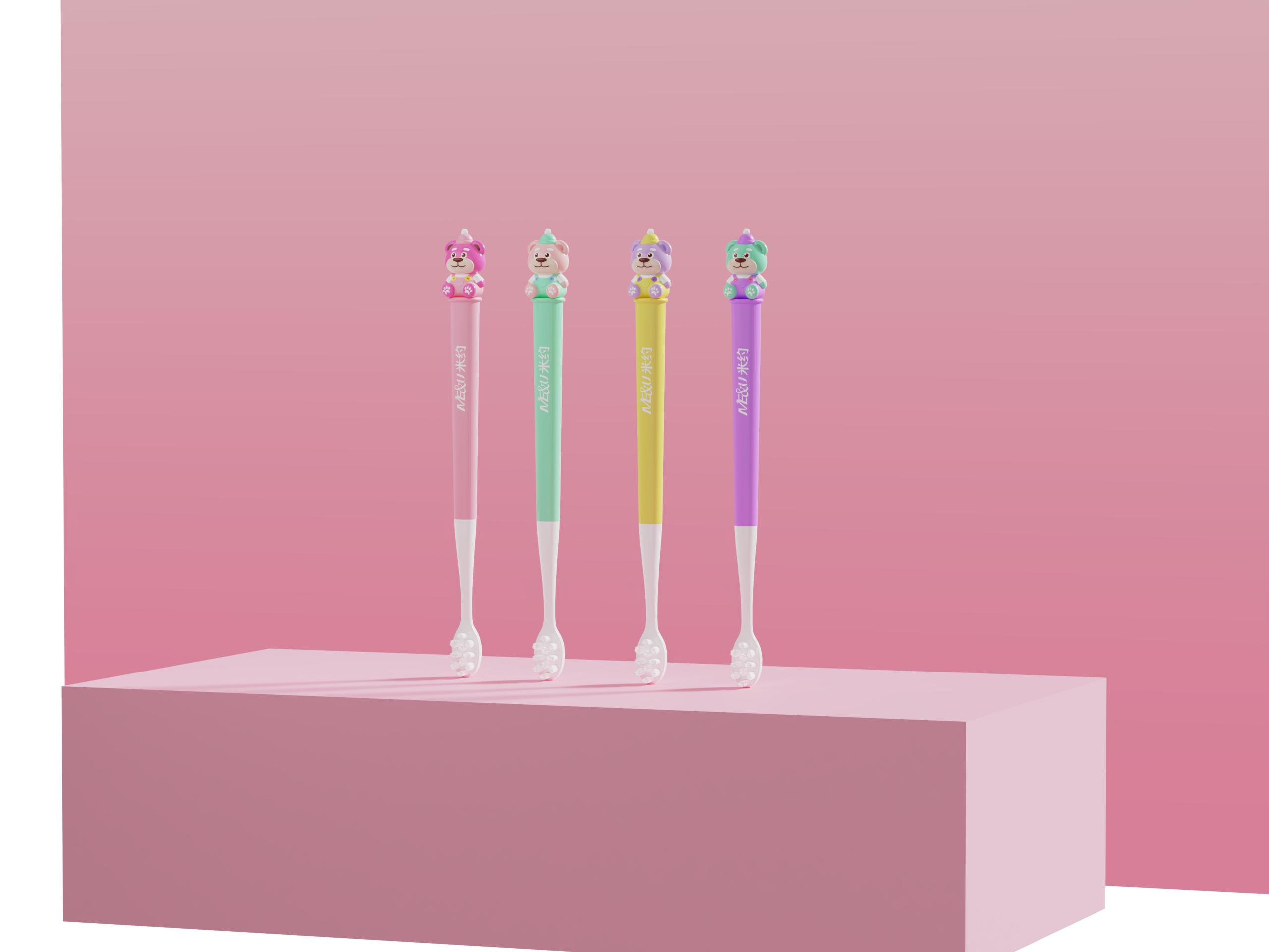

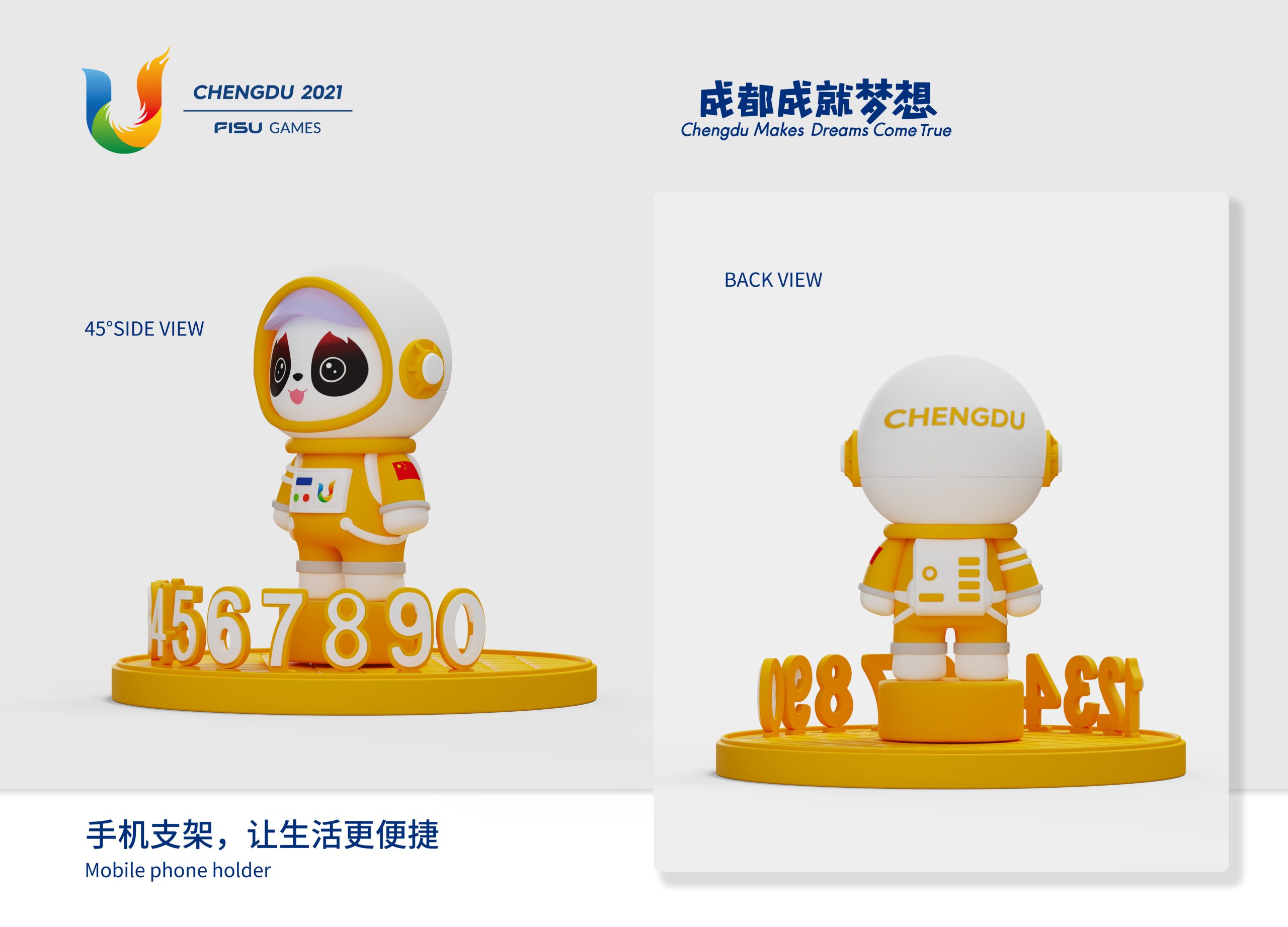

Tiancheng International Creative Technology (HONG KONG) Co., Ltd. is a one-stop custom manufacturer and solution provider specializing in plastic (PVC soft rubber/silicone) promotional gifts and IP derivatives. We hold WCA certification, which lays a solid foundation for our standardized production, IP protection and global cooperation. We have established in-depth cooperation with top global IPs such as Disney and Line Friends, a testament to our excellent IP integration capabilities and industry-recognized product quality.

We are committed to supporting our partners in realizing the whole-process transformation of products from initial idea to market launch. Endowed with strong custom capabilities, we can tailor personalized solutions according to customers' diverse needs. Meanwhile, we boast efficient rapid prototyping capabilities to shorten the product development cycle significantly. We also support MOQ (Minimum Order Quantity) requirements, making customization more flexible and accessible for customers of different scales. With profound manufacturing expertise, advanced technical capabilities and comprehensive one-stop services, we have become the partner of choice for many leading brands and global retailers.

Our customized products cover a wide range of application scenarios, and we are widely recognized in the industry for delivering innovative products, reliable manufacturing quality, and tailored technical solutions. We look forward to cooperating with global partners to create more value and achieve a win-win partnership.