Silicone is a versatile synthetic material used in countless industries—from automotive and medical devices to personal care products and construction. Its unique properties, including heat resistance, flexibility, and chemical stability, make it indispensable in modern manufacturing. But have you ever wondered, how is silicone produced step by step? In this comprehensive guide, we’ll break down the entire silicone manufacturing process, detail the key machines involved and how to use them (like silicone injection molding machine types and usage guide), answer common questions, and share insights tailored for industry professionals. Whether you’re a manufacturer, buyer, or curious enthusiast, this guide will demystifysilicone production methods for industrial use, including tips on how to choose raw materials for silicone rubber manufacturing 以及 silicone curing time and temperature control tips.

Key Raw Materials for Silicone Production

-

Silicon metal (extracted from silica sand)

-

Chlorine gas (for producing silicon tetrachloride)

-

Water (for hydrolysis reactions)

-

Vinyl silicone oil (a key raw material for silicone rubber manufacturing)

-

Catalysts (e.g., platinum for addition curing)

-

Reinforcing fillers (e.g., fumed silica to enhance strength)

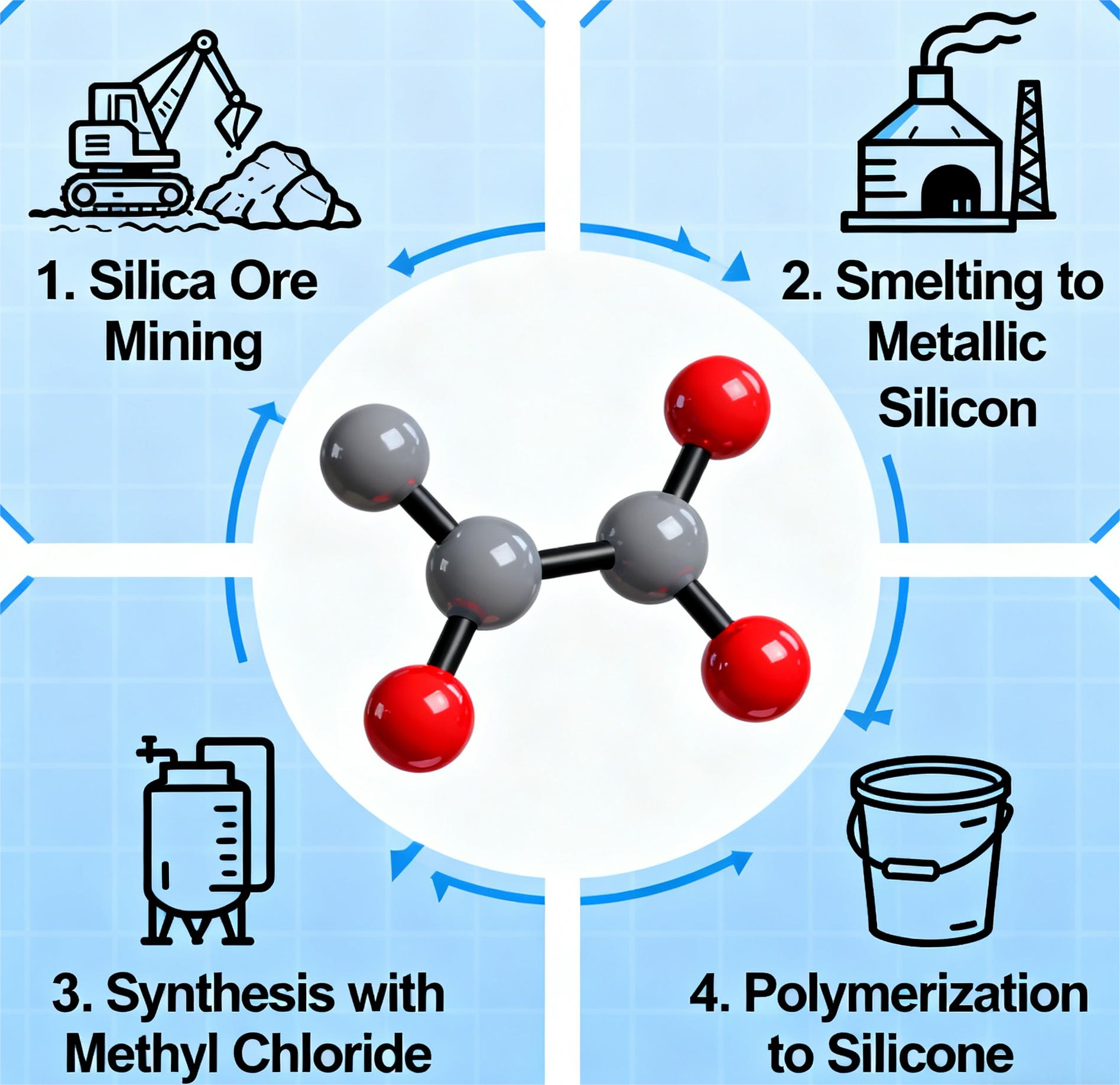

Step-by-Step Silicone Manufacturing Process: From Raw Materials to Finished Products

Step 1: Extract Silicon Metal from Silica Sand

Key Machines & Usage

-

Electric Arc Furnace:

-

What it does: Uses intense electric heat (1,800–2,000°C) to reduce silica sand to silicon metal. A mixture of silica sand and carbon (coke or coal) is fed into the furnace, where carbon reacts with oxygen in silica to form carbon dioxide, leaving pure silicon behind.

-

How to use it: Load the silica-carbon mixture into the furnace’s graphite electrodes. Apply an electric current to generate the required temperature. The reaction takes 6–8 hours, after which molten silicon is tapped from the furnace. Allow the silicon to cool and solidify into ingots.

-

Step 2: Produce Chlorosilanes (Silicon Tetrachloride)

Key Machines & Usage

-

Fluidized Bed Reactor:

-

What it does: Facilitates the reaction between silicon metal and chlorine gas to form chlorosilanes. Silicon metal powder is fluidized (suspended in a gas stream) while chlorine gas is injected, creating a uniform reaction environment.

-

How to use it: Grind silicon ingots into fine powder and load it into the reactor. Heat the reactor to 250–300°C. Inject chlorine gas into the fluidized bed. The reaction produces silicon tetrachloride vapor, which is cooled and condensed into a liquid for collection.

-

-

Condenser System: Cools the chlorosilane vapor to a liquid state for storage and further processing. Ensure the condenser temperature is set to -20°C to -30°C for efficient condensation.

Step 3: Hydrolysis of Chlorosilanes to Form Siloxane Monomers

Key Machines & Usage

-

Hydrolysis Reactor:

-

What it does: Mixes chlorosilanes with water in a controlled environment to trigger hydrolysis. The reaction produces siloxane monomers (e.g., dimethyldichlorosilane hydrolysis yields dimethylsiloxane) and hydrochloric acid (HCl).

-

How to use it: Add liquid chlorosilanes and water to the reactor in a 1:2 ratio. Maintain a temperature of 20–40°C to prevent excessive HCl vapor release. Stir the mixture continuously for 1–2 hours to ensure complete reaction. Separate the siloxane monomer layer from the aqueous HCl layer using a separator.

-

-

HCl Scrubber: Removes and neutralizes hydrochloric acid byproducts to comply with environmental regulations. Pass the HCl vapor through a sodium hydroxide (NaOH) solution to form salt and water.

Step 4: Polymerization of Siloxane Monomers

Key Machines & Usage

-

Polymerization Reactor:

-

What it does: Uses heat and catalysts to initiate polymerization, where siloxane monomers form long, cross-linkable polymer chains. Common catalysts include potassium hydroxide (KOH) for condensation polymerization or platinum for addition polymerization.

-

How to use it: Load siloxane monomers and the appropriate catalyst into the reactor. Heat the mixture to 100–150°C for condensation polymerization or 80–120°C for addition polymerization. Maintain constant stirring for 4–6 hours to ensure uniform chain growth. Add chain terminators (e.g., trimethylchlorosilane) to control polymer length and properties.

-

-

Vacuum System: Removes unreacted monomers and volatile byproducts from the polymer mixture. Operate the vacuum at 0.1–1 mbar during the final stage of polymerization to improve polymer purity.

Step 5: Compounding (Adding Fillers & Additives)

Key Machines & Usage

-

Internal Mixer (Banbury Mixer):

-

What it does: Mixes the polymer with reinforcing fillers (e.g., fumed silica), plasticizers, antioxidants, and colorants to create a uniform silicone compound. The mixer uses rotating blades to apply shear force, ensuring thorough dispersion of additives.

-

How to use it: Load the base polymer into the mixer. Heat the chamber to 80–100°C to soften the polymer. Gradually add fillers and additives while the blades rotate at 50–100 RPM. Mix for 20–30 minutes, then discharge the compound onto a mill for further processing.

-

-

Two-Roll Mill: Refines the compounded silicone to remove air bubbles and ensure uniform consistency. Pass the compound between two rotating rolls (temperature: 60–80°C) for 5–10 minutes, adjusting roll spacing to achieve the desired thickness.

Step 6: Shaping (Molding/Extrusion) the Silicone Compound

Key Machines & Usage: Injection Molding, Extrusion & Thermoforming

-

Silicone Injection Molding Machine (for LSR and HCR):

-

What it does: Injects molten silicone into a preheated mold to create precise, complex shapes (e.g., medical catheters, automotive seals). Common types include plunger, auger, direct drive, and all-electric models—learn more in our silicone injection molding machine types and usage guide.

-

How to use it:

-

For Liquid Silicone Rubber (LSR): Load two LSR components (catalyst and crosslinker) into the dosing unit. Mix them in a static/dynamic mixer, then inject into a mold preheated to 180–220°C. Apply pressure (100–200 bar) to fill the mold, then cure for 1–5 minutes .

-

For High Consistency Rubber (HCR): Feed preformed HCR strips into the screw extruder. Heat and mix the compound, then inject into a heated mold (160–180°C) under 150–250 bar pressure. Cure for 5–15 minutes .

-

-

-

Silicone Extruder Machine:

-

What it does: Produces continuous silicone products (e.g., hoses, gaskets, profiles) by forcing the compound through a die of the desired shape.

-

How to use it: Feed the compounded silicone into the extruder’s hopper. The screw conveys and heats the silicone (80–120°C) to a pliable state. Force the silicone through the die at 50–100 bar pressure. Cool the extruded product with water to set its shape, then cut to length.

-

-

Silicone Thermoforming Machine:

-

What it does: Heats silicone sheets until pliable, then forms them over a mold using vacuum or pressure (ideal for packaging, automotive components) .

-

How to use it: Load a silicone sheet into the machine. Heat the sheet to 120–160°C until flexible. Lower the mold and apply vacuum (to draw the sheet over the mold) or pressure (for detailed shapes). Cool the formed product, then trim excess material.

-

Step 7: Curing (Vulcanization)

Key Machines & Usage

-

Hot Air Oven:

-

What it does: Uses dry heat to cure silicone products. Ideal for small to medium batches (e.g., seals, gaskets).

-

How to use it: Place the shaped silicone products on racks in the oven. Set the temperature to 150–200°C and cure for 10–30 minutes (depending on product thickness). Ensure proper air circulation for uniform curing.

-

-

Continuous Vulcanization Line (CV Line):

-

What it does: Cures continuous silicone products (e.g., extruded hoses) efficiently in high-volume production.

-

How to use it: Feed the extruded silicone through a heated chamber (180–220°C) at a constant speed (1–5 m/min). The product cures as it moves through the chamber, then cools before winding or cutting.

-

Step 8: Finishing & Quality Control Methods for Silicone Manufacturing

Key Machines & Usage

-

Trimming Machine: Cuts excess material from molded/extruded products (e.g., flash from injection molding). Use a laser trimmer for precision or a mechanical trimmer for high-volume production.

-

Quality Control Equipment:

-

Hardness Tester: Measures Shore hardness (e.g., Shore A for flexible silicone) to ensure product consistency.

-

Tensile Tester: Evaluates tensile strength and elongation properties.

-

Visual Inspection Station: Checks for surface defects (bubbles, cracks) using magnifying lenses or automated cameras.

-